网站公告

more- Affiliate Ma... 25-04-13 16:31

- Make Money O... 25-04-13 16:30

- How Is It Po... 25-04-13 16:28

- Online Backu... 25-04-13 16:27

What Is Taken Into Account Small Engine Repair?

CoraToft3820695 2025.04.12 17:54 查看 : 2

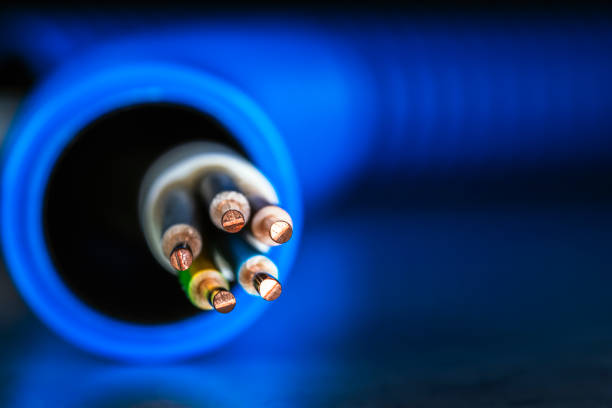

A friction bearing relies on lubricants to reduce friction. A nonfriction bearing uses exhausting steel rollers or balls to stop put on, though it too requires some lubrication. At the larger finish of the connecting rod is a bearing that allows rotation across the moving crankshaft. Step 3: Wipe sediment from the tip of the filter element. The small finish is attached to the piston pin. The three sorts of carburetors generally utilized in small engines are natural draft, updraft, and downdraft. Tools and toys powered by small engines can cost anywhere from $one hundred to $10,000. Caution: An incorrectly adjusted governor can cause the small engine to function at excessively high speeds and damage or destroy it. Surfaces at these factors have to be free of burrs that would chafe the wire and harm its insulation. The 110-120-volt circuits have two conductors -- one neutral (white) wire and one scorching (black) wire. Step 3: Clean battery terminals using a small amount of baking soda and a stiff wire brush. Servicing your small engine device or toy regularly affords many benefits over the Wait-Until-It-Breaks Maintenance Program. However, to ensure lengthy-time period performance, perform the following inspection on a regular basis.

Regular service offers you an opportunity to visually examine the complete engine and related components for injury, put on, and other potential problems. Step 3: Once the idle speed has been set, alter the idle mixture till the engine runs smoothly. To maintain your small engine, you will have to make sure the carburetor's speed and mixture are correctly adjusted. The spark must be appropriately timed to achieve the spark plug at the precise moment when the piston is at the top of its travel and the gas-air mixture is absolutely compressed. If you have the grounded sort, you will need to buy a receptacle that has a floor terminal screw and slots for 3-prong grounded plugs. If in case you have a dwell meter, refer to the unit's working directions and the ignition specifications to determine what dwell angle setting is right and learn how to set it. Because the load slows the engine down, the governor opens the throttle to return the engine to a set speed. Maintaining a gas system includes servicing the gas filter, air cleaner, gas tank, and gasoline traces; adjusting the carburetor; and adjusting the governor.

Regular service offers you an opportunity to visually examine the complete engine and related components for injury, put on, and other potential problems. Step 3: Once the idle speed has been set, alter the idle mixture till the engine runs smoothly. To maintain your small engine, you will have to make sure the carburetor's speed and mixture are correctly adjusted. The spark must be appropriately timed to achieve the spark plug at the precise moment when the piston is at the top of its travel and the gas-air mixture is absolutely compressed. If you have the grounded sort, you will need to buy a receptacle that has a floor terminal screw and slots for 3-prong grounded plugs. If in case you have a dwell meter, refer to the unit's working directions and the ignition specifications to determine what dwell angle setting is right and learn how to set it. Because the load slows the engine down, the governor opens the throttle to return the engine to a set speed. Maintaining a gas system includes servicing the gas filter, air cleaner, gas tank, and gasoline traces; adjusting the carburetor; and adjusting the governor.

A governor is a gadget that controls the speed of the engine as the load modifications. Turn the excessive-speed adjustment needle ahead and backward till the best pace setting is discovered. Adjust the idle-speed needle until the beneficial idle velocity is discovered. Step 2: Apply the recommended grade of lubricating grease. Step 1: Remove the cap from the gas tank. Some small engines use oil filters to take away contaminants from the circulating oil. Unfortunately, there is no common adjustment sequence for small engine governors. For people who need to completely power a whole home with the solar's rays, there are methods out there to convert and retailer extra power in the form of battery energy. Step 3: Check the gasoline line and siphon bulb, if there's one, by squeezing them and inspecting for cracks. If broken, change with a line or a bulb of the identical inside diameter. Be sure the 2 boxes receive the identical quantity of sunlight. Make sure it's accepted to be used with gasoline. Still different small engines use disposable in-line gas filters manufactured from pleated paper. A small engine ignition consists of the ignition controller (mechanical-breaker, capacitor-discharge, or transistor-managed), spark plugs, flywheel, and wiring. Step 2: Service the ignition controller (mechanical-breaker, capacitor-discharge, or transistor-controlled) as described at the bottom of this page.

Step 2: Service ignition controller. Step 3: Service spark plug(s). Step 5: Lubricate the management before reassembly. Step 4: Inspect the cable insulation for corrosion and breaks; replace as wanted. If full lever movement does not fully transfer the carburetor throttle, adjust the cable as required. Some, like your cable field or DVD participant, are really ghoulish: They drink vitality even when not in use. Filters: Friction happens. Moving components wear, even with the best lubricants. You may decide up all needed components and lubricants in one journey to the elements store. A service chart will help you establish widespread service necessities as well as observe what service has been completed. This experiment will help answer that question. You need to have copies of your utility bills nearby, insulated power cable which is able to let you know how much energy you consume. Touching a charged steel body of the equipment whereas concurrently touching a water faucet or a radiator will make the current surge via you.

?? 0

Copyright © youlimart.com All Rights Reserved.鲁ICP备18045292号-2 鲁公网安备 37021402000770号